Description

https://www.jsksintelligent.com/Vacuum-Spray-System-Skid.html

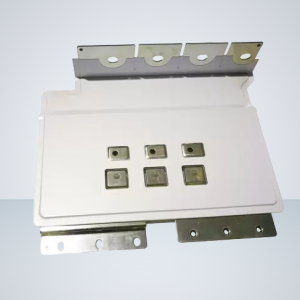

Vacuum Spray System Skid Product Details

The vacuum spray system skid is a highly efficient and compact solution designed to create a reliable vacuum environment for various industrial applications. This integrated unit combines a vacuum pump and ejector system to provide precise control and stable operation. The vacuum ejector system is the core of this skid, utilizing the power of high-velocity fluid flow to generate vacuum quickly and efficiently. It is widely used in industries such as chemical processing, pharmaceuticals, food processing, and power generation.

System Composition

The vacuum spray system skid consists of several key components that work together to achieve optimal performance:

Ejector: This is the heart of the vacuum ejector system. It includes a nozzle, mixing chamber, and diffuser, and is responsible for generating vacuum through the Venturi effect. The high-velocity fluid flow creates a low-pressure zone, which draws in and expels gases or vapors.

Power Fluid Supply System: This system provides the high-pressure steam, compressed air, or liquid (such as water) needed to drive the vacuum ejector system.

Vacuum Chamber/Container: This component connects to the equipment or system that needs to be evacuated, ensuring a stable vacuum environment.

Condenser (for steam ejector systems): In steam-driven vacuum ejector systems, the condenser plays a crucial role by condensing the mixed gases to improve efficiency and reduce the load on the downstream vacuum pump.

Control System: This system regulates the flow rate, pressure of the power fluid, and the vacuum level, ensuring precise control of the vacuum spray system skid.

Working Principle

The vacuum spray system skid operates on a well-defined principle to achieve efficient vacuum generation:

Power Fluid Acceleration: High-pressure fluid (such as steam) is accelerated through the nozzle of the vacuum ejector system, creating a low-pressure zone.

Gas Ingestion: The low-pressure zone draws in the gas to be evacuated from the vacuum chamber into the mixing chamber of the vacuum ejector system.

Mixing and Compression: The ingested gas mixes with the power fluid and is compressed as it passes through the diffuser, which decelerates the fluid and increases its pressure before discharging it.

Condensation: In steam ejector systems, the condenser cools and condenses the steam, reducing the load on the downstream vacuum pump and enhancing the overall efficiency of the vacuum spray system skid.

Core Advantages

The vacuum spray system skid offers several key advantages that make it a preferred choice for industrial applications:

No Mechanical Moving Parts: The design of the vacuum ejector system eliminates the need for mechanical moving parts, resulting in low maintenance costs and a long service life.

Corrosion and High-Temperature Resistance: The vacuum ejector system can handle corrosive or high-temperature gases, making it suitable for harsh environments such as chemical and metallurgical industries.

Rapid Startup: The vacuum spray system skid does not require preheating, allowing for instant vacuum generation and quick startup.

Multi-Stage Capability: Multiple ejectors can be connected in series to achieve higher vacuum levels. For example, a three-stage steam ejector vacuum system can reach vacuum levels of 1~0.1 mbar, making it ideal for applications requiring high vacuum.

Typical Applications

The vacuum spray system skid is widely used across various industries due to its versatility and reliability:

Chemical Industry: Ideal for distillation, drying, and degassing processes.

Pharmaceutical Industry: Used in vacuum systems for freeze dryers, ensuring precise control and high efficiency.

Power Industry: Employed in vacuum extraction for steam turbine condensers, enhancing overall system performance.

The future of the vacuum spray system skid looks promising, with advancements in technology expected to further enhance its capabilities. Future developments may include integration with mechanical vacuum pumps to optimize energy efficiency and the implementation of intelligent control systems, such as PID regulation of vacuum levels, to enhance performance and adaptability.

In summary, the vacuum spray system skid is an essential solution for industrial vacuum generation, particularly in applications requiring oil-free, corrosion-resistant, or high-capacity vacuum environments. Its simple structure, high reliability, and strong adaptability make it a preferred choice for a wide range of industries.

Reviews

There are no reviews yet.