Description

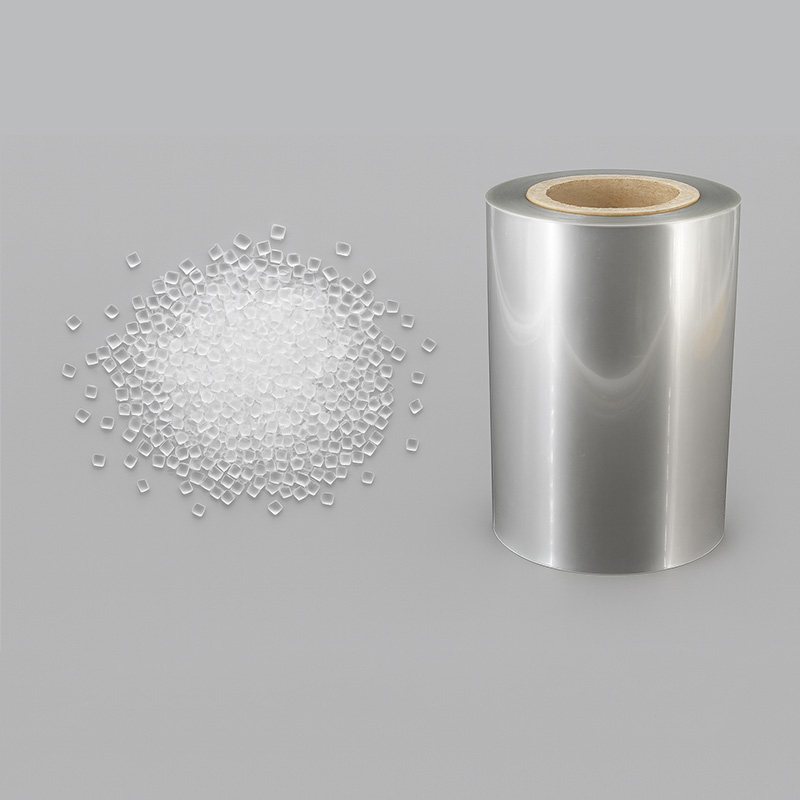

Our PETG resin is a premium thermoplastic polyester designed for PETG shrink shrink sleeve labels, and 3D printing filament production.

It combines high transparency, excellent toughness, low processing temperature, and stable shrink performance, making it a reliable alternative to PVC and standard PET materials.

This PETG material is widely used in packaging, labeling, and additive manufacturing industries, meeting the growing demand for environmentally friendly and high-performance plastics.

Technical Data Sheet

|

Items |

Unit |

Test Method |

WS-501 |

|

1.Property |

|||

|

IntrinsicViscosity |

dL/g |

Ubbelodhe viscometerUbbelodhe viscometer |

0.750±0.015 |

|

Specific Gravity |

g/cm3 |

ASTM D792 |

1.27 |

|

Moisture Absorption |

% |

ASTM D570 |

0.15 |

|

2.Mechanical |

|||

|

Tensile Strength @Yield |

kgf/cm² |

ASTM D638 |

496 |

|

Tensile Strength @Break50mm/min(2 inch/min) |

kgf/cm² |

ASTM D638 |

281 |

|

Elongation @Yield |

% |

ASTM D638 |

3.7 |

|

Elongation @Break |

% |

ASTM D638 |

136 |

|

Flexural Strength |

kgf/cm2 |

ASTM D790 |

620 |

|

Flexural Strength |

kgf/cm2 |

ASTM D790 |

20800 |

|

Low temperature falling dart |

g |

ASTM D358 |

791 |

|

Atmospheric temperature |

g |

ASTM D358 |

1701 |

|

Izod Impact Strength Notched@23℃(73℉) |

J/m |

ASTM D256 |

98 |

|

3. Hardness |

|||

|

Rockwell Hardness |

℃ |

R-scale |

106 |

|

4. Thermal |

|||

|

Heat Distortion Temperature |

℃ |

ASTM D648 |

77 |

|

Melting Index |

g/10min |

ASTM D1238-04 |

1.2 |

|

Melting point |

℃ |

≥196±2 |

|

|

5. Electric Properties |

|||

|

Surface Resistivity |

Ohm |

ASTM D257 |

10¹⁶ |

|

Volume Resistivity |

Ohm·cm |

ASTM D257 |

10¹⁵ |

|

Dielectric Strength (Short time, 500V/sec) |

kV·mm |

ASTM D149 |

16 |

|

Dielectric Constant (1 kHz) |

– |

ASTM D150 |

2.6 |

|

Dielectric Constant (1 MHz) |

– |

ASTM D150 |

2.4 |

|

Dissipation Factor (1 kHz) |

– |

ASTM D150 |

0.005 |

|

Dissipation Factor (1 MHz) |

– |

ASTM D150 |

0.023 |

|

6. Flammability |

|||

|

UL Flammability Classification (1.00mm) |

– |

UL 94 |

HB |

|

UL Flammability Classification (1.50mm) |

– |

UL 94 |

HB |

|

UL Flammability Classification (3.00mm) |

– |

UL 94 |

V-2 |

|

7. Optical Properties |

|||

|

Haze |

% |

– |

<1.0 |

|

Transmittance |

% |

ASDM D541 |

90 |

|

Refractive Index |

– |

ASDM D542 |

1.52 |

Applications

WS-501

For Film Usage

WS-501 PETG resin is a high shrink film grade special material, which can be

used to produce various specifications of high-shrinkage film.The uniaxial

oriented shrink films can be applied to sleeve label printing of different kinds

of canning, bottles and other containers.

For 3D Filaments Application

It can also be used for 3D print filament.PETG filament is stronger and

offers more impact resistance than acrylic, ABS and PLA filaments.It's toughness

and resistance make it a dependable material for various projects.

Packaging method

Reviews

There are no reviews yet.